Cheaper and More Sustainable Materials are Compelling

Performance Gains Continue

In looking at the big picture regarding climate change, and metrics that seem to be steadily trending in the wrong direction, it is easy to overlook progress being made by companies and organizations researching new technology solutions on a global scale. A key area of recent progress: sodium batteries for vehicle, industrial and grid storage applications.

It’s fairly obvious that new energy storage technologies are needed to support the clean energy transition. Incorporation of intermittent renewable energy sources, such as wind and solar, drive the need for significant amounts of energy storage. Electric vehicles (EVs) have reached 10% of global sales. Although lithium-ion batteries are still the performance benchmark in these applications, there’s nowhere near enough of the needed raw materials available to continue dependence on this technology for every application.

Battery Materials and Performance

We won’t go into the details of battery chemistry and construction here, but we’ll address the materials and some of the key performance characteristics to provide a basic comparison of Li-ion (lithium-ion) and Na-ion (sodium-ion). We’re just going to scratch the surface.

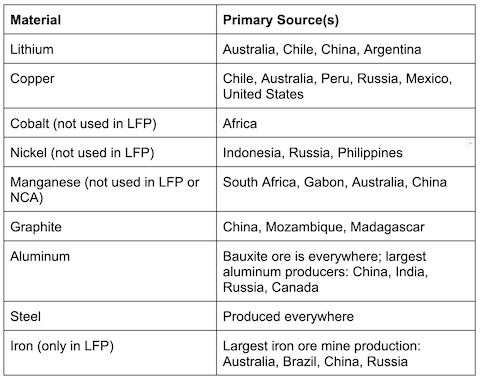

The most popular chemistries of Li-ion batteries include NMC (nickel/manganese/cobalt) variants, NCA (nickel/cobalt/aluminum) and LFP (lithium/iron phosphate). The materials used include:

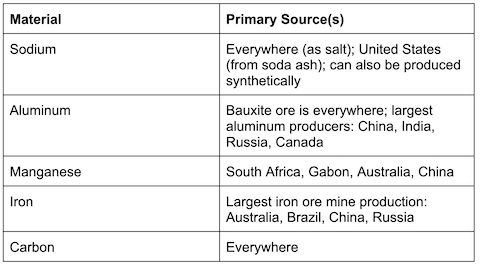

Versions of Na-ion batteries have been around for a few decades. We’ll focus on just the chemistry of those that are commercialized. The materials used include:

One other type of material used in some Na-ion batteries is Prussian blue or white. These are widely-used pigments in color paints, textiles, and other commercial products. The Prussian pigments are able to efficiently transfer electrons, so they’re an effective component in Na-ion battery electrode configurations.

Na-ion advantages over Li-ion:

- Safer: not susceptible to thermal runaway, even after physical damage

- Better performance at low temperatures

- Able to provide slower discharge rates

- Capable of full discharge without the risk of catastrophic failure upon recharge

- Less expensive (sodium cost is less than 5% that of lithium)

- No dependency on scarce materials such as cobalt and nickel

Li-ion advantages over Na-ion:

- Faster charging rate

- Higher energy density (based on both weight and volume); some commercial Li-ion units are near 300 Wh/kg

- Higher voltage

Recent Developments

CATL (Contemporary Amperex Technology Ltd.), the world’s largest manufacturer of EV batteries, announced it will have Na-ion batteries in commercial EVs by the 4th quarter of this year. CATL says the batteries will have an energy density surpassing 200 Wh/kg.

BYD, an energy storage and vehicle manufacturer, announced plans to produce a compact EV with Na-ion batteries in 2023.

Natron Energy, in partnership with battery producer Clarios International, will begin mass production of Na-ion batteries at a facility in Michigan later this year. Natron produces Na-ion battery packs for data centers and industrial applications.

Pacific Northwest National Laboratory (PNNL), in collaboration with renewable energy company Nexceris and its new business Adena Power, developed and tested a Na-ion prototype battery for grid energy storage. They project the technology can achieve an energy density of up to 100Wh/kg while providing the long-term energy discharge capabilities needed in grid application.

Farasis Energy, a Chinese battery manufacturer, will supply Jiangling Motors Electric Vehicle (JMEV) with Na-ion battery packs for a compact EV.

In 2022, United Airlines Ventures invested in Natron Energy to help electrify its ground operations.

Summary

Na-ion battery technology has picked up significant momentum in the past couple years and may drive a significant iteration of the battery industry. Safety, lower costs and lowered dependency on scarce materials are compelling drivers of development.

As the transition to clean energy moves forward there will be many new technologies that provide effective solutions. This is just one example of how people, when provided with the necessary resources, can find new paths forward.