Great Power, But Great Responsibility for Public Safety

A Perspective on Past Nuclear Plant Incidents

As the effects of climate change become increasingly apparent, nuclear power is getting more attention as a viable clean energy source. Nuclear reactors produce no GHG emissions. Nuclear power plants provide steady, predictable power that can be complementary to intermittent renewable sources.

Countries have embraced nuclear energy to varying degrees. France is at the high end of the range, producing 70% of its electricity from nuclear reactors. The US is at 19%. The global total is about 10%.[1] There are currently about 440 reactors operating globally with 53 new units under construction.[2]

Nuclear power has some negative aspects, including:

- High initial cost for nuclear plant construction and long time to deployment

- Spent fuel radioactive waste

- Safety

I’m a proponent of nuclear power, but I fully understand why many people have concerns about safety. Past high-visibility, high-impact accidents are valid reasons for this concern. How do those incidents relate to current and future nuclear plants? Let’s take a look.

Background

In composing this article, I’ve applied my engineering experience in reviewing available public information on past nuclear accidents. About 20 years of my engineering career included design, engineering, construction, operations, and maintenance responsibilities for tens of big data centers. These facilities are considered mission-critical and are expected to run flawlessly 365 days per year, year after year. The expectations for nuclear power plants are very similar, and there are numerous comparable systems in each type of facility.

When facility failures (“incidents”) occur, root cause analysis (RCA) is performed to figure out what happened. Systems and processes are then modified or otherwise improved to prevent recurrence. The US Nuclear Regulatory Commission (NRC) makes nuclear facility incident reports (LERs, licensee event reports) public on its website. In the past, I regularly read the reports to see what could be learned for application in the data center industry. The similarity between the LERs and what we experienced in data center incidents was striking. Some example root causes common to both types of facility include:

- Sensor and instrumentation failures

- Design flaws

- Poor construction workmanship

- Redundant systems failures

- Single point vulnerabilities (SPVs)

- Operator error (human error)

Note that in many complex facility incidents, multiple smaller failures contribute to the overall outcome. This is the case in the three significant nuclear accidents we’ll look at: Three Mile Island, Chernobyl and Fukushima Daiichi. We’ll also look at a lesser-known “close call” event at Davis-Besse.

Keep in mind that the overall safety record of the nuclear energy industry is quite good in comparison to other energy source industries such as coal and natural gas. However, the high-visibility nuclear accidents that have occured tend to dominate conversations about safety.

Three Mile Island (TMI) 28 March 1979, Near Harrisburg, PA, USA

This was a serious incident that resulted in the release of radioactive materials to the atmosphere. It’s an example of “life imitating art”, since the movie “The China Syndrome” had been released about 2 weeks prior to the accident. The movie portrays a fictitious reactor core meltdown in a nuclear power plant. A “China syndrome” is a hypothetical condition where the melted nuclear material breaches the reactor containment and burns its way through the earth to the other side, presumably China.

The nuclear industry derided the movie. John Taylor, an executive at Westinghouse (a reactor manufacturer), called the movie “an overall character assassination of an entire industry”. Dr. Norman Rasmussen, a nuclear engineering professor at MIT said “Frankly, I don’t believe a serious accident could ever happen. I am a scientist and I don’t believe in zeroes. But I do believe in redundant systems and the capability of people and systems to take preventive action.” [3]

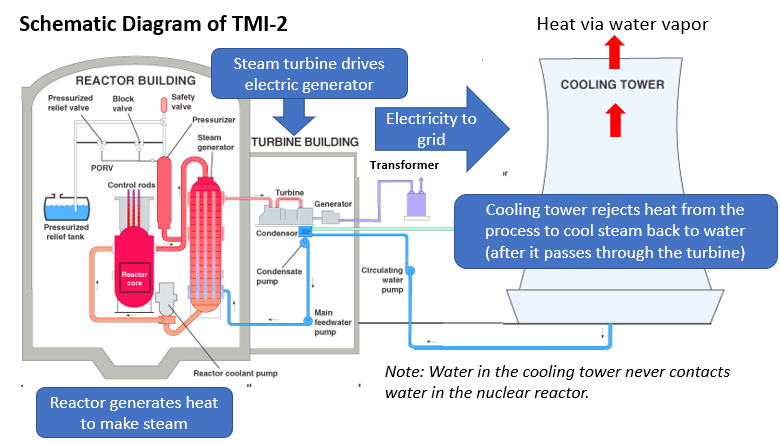

Here’s a basic schematic diagram illustrating the major components of a nuclear power plant. The basic concept is simple: a controlled nuclear reaction generates heat which produces steam to drive a turbine. The turbine spins an electrical generator producing electricity for distribution to customers. Very complex machinery and systems are required to make this simple concept a reality.

On the day of the incident, starting at 4:00 AM, a chain of events and circumstances lead to a partial core meltdown. This is an abridged summary:

- A minor secondary cooling loop malfunction caused a reactor shutdown

- A pressure relief valve failed to close after a programmed time delay of about 10 seconds, but monitoring/control instrumentation did not correctly indicate this condition, so operators had no idea the valve was open. The valve stayed open for 2 hours and 20 minutes, permitting the escape of about 30,000 gallons of slightly radioactive primary cooling water. [14]

- The control room, typical for that era, was a confusing mess of visual alarm panels, analog gauges, audible alarms and paper printouts. This approach made it very difficult for operators to fully understand what was occurring in the plant.

- Primary cooling water boiled away, causing exposure of the reactor’s fuel rods and overheating. The fuel rods were damaged and released radioactive material into the cooling water.

- At 6:50 AM, nearly 3 hours after the start of the incident, plant officials publicly declared a “site emergency,” a procedure implemented whenever an event posed the possibility of an “uncontrolled release” of radiation to the immediate environment. [14]

- A hydrogen bubble formed in the reactor pressure vessel. Core heat and steam result in hydrogen gas generation due to the rapid oxidation of the zirconium alloy tubes (“fuel cladding”) that surround the low-enriched uranium fuel pellets. Under the right conditions, the presence of hydrogen represents a potential explosion hazard. It took plant operators several tense days to eventually determine there was no explosion hazard based on the amount of hydrogen and oxygen present.

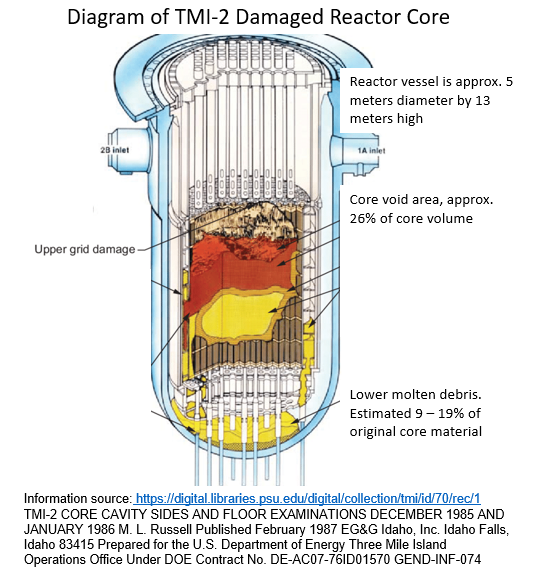

After things were brought under control, a subsequent examination of the reactor core years later found that 45% of the core, 62 tons, had melted. It was a very serious meltdown, but not a China Syndrome.

During the accident there was a release of krypton gas with a relatively short half-life.[4] The nuclear industry claims there was no harmful release of other radioactive materials, but the monitoring instrumentation was limited at that time. It is not likely anyone knows definitively how much radiation was released. Michio Kaku, PhD, a renowned theoretical physicist, in the 2022 Netflix documentary “Meltdown: Three Mile Island”, says: “Nobody really knows how much radiation came out because we don’t have the numbers. The estimates of radiation damage at Three Mile Island neglect all sorts of different kinds of variables. Anyone who says definitively how much radiation came out of that accident is either lying or a fool.” (Episode 2)

The psychological stress for residents in the vicinity of the plant, in the state of Pennsylvania and for the US was very real. The confusing communications by various government agencies and the plant owner/operator further contributed to the emotional trauma of this incident. About 140,000 people voluntarily left the vicinity of the plant. The President of the United States, Jimmy Carter, visited the site on April 1, 1979, to reassure the American people that things were under control.

The plant cleanup took 12 years and cost over $US 900 million (close to 2 billion in today’s dollars). It was not without controversy, including public pushback, scores of lawsuits and a federal whistleblower case. [5] 20 years after the accident, a judge dismissed 2,000 lawsuits for damage claims.[15]

How could such a serious event occur?

- The industry was complacent. From the “Report of The President’s Commission on The Accident at Three Mile Island”, Page 9: “After many years of operation of nuclear power plants, with no evidence that any member of the general public has been hurt, the belief that nuclear power plants are sufficiently safe grew into a conviction.”

- An additional example of complacency: a similar valve failure at Davis- Besse in September 1977 and subsequent warnings from an NRC official went unheeded.

- Poor instrumentation and poorly designed control rooms resulted in incorrect or conflicting information for operators, which resulted in some incorrect human actions

- There was no redundancy for control and monitoring of the relief valve that failed to close

Chernobyl 26 April 1986, Ukraine

Chernobyl was a mess from start to finish, resulting in a terrible nuclear accident. The basic design of the reactor was flawed and inadequate training led to numerous operational errors. The reactor explosion and fire released an estimated 5% of the reactor core into the atmosphere, depositing radioactive material in many parts of Europe.[6]

Some of the horrible impacts of this accident:

- Two people died when the explosion occurred and 28 more died of acute radiation poisoning within weeks after the accident.

- The United Nations Scientific Committee on the Effects of Atomic Radiation tabulated 5,000 cases of thyroid cancer (and 15 associated deaths) as a result of the accident

- 350,000 people had to be evacuated

- Significant environmental contamination in an exclusion zone encompassing about 2,600 km2 (1,000 sq mi). 35 years later crops outside the exclusion zone still show Strontium-90 contamination. [7]

There’s not much value in analyzing “lessons learned” from this accident since the flawed reactor design was the root cause. Fortunately, there are only 8 of these Soviet designed RBMK (an acronym for Reactor Bolshoi Moschnosti Kanalynyi “Channelized Large Power Reactor”) reactors still in operation. All are in Russia and they’ve been fitted with safety upgrades. Surprisingly, these units are scheduled to continue operating for years to come.[8]

Davis Besse 16 February 2002, Oak Harbor, OH, USA

This incident was an example of a “close call”. During corrective maintenance while the reactor was shut down, it was discovered that the reactor core pressure vessel was nearly breached, It had just ⅜” (9.5 mm) of stainless steel remaining after 6.63” (16.8 cm) of carbon steel had corroded over a 10-year period.[9] If the pressure vessel had breached, a massive loss of cooling incident could have resulted.

How could this situation occur? The NRC task force identified three key points: [10]

- Davis-Besse failed to ensure plant safety issues received appropriate attention

- Davis-Besse, the nuclear industry, and the NRC had not adequately reviewed relevant operating experience at other nuclear power plants

- The NRC’s assessment of Davis-Besse’s safety performance did not consider all available information..

I’d characterize the root cause of this incident as general complacency, consistent with attitudes that evolve over time when everything has been running just fine. It’s easy to fall into this behavior, and it takes disciplined operational programs to overcome. Let’s hope the industry hasn’t fallen back into the same level of complacency.

Fukushima Daiichi 11 March 2011, Fukushima Prefecture, Japan

It may sound odd, but nuclear power plants depend on external sources of power for startup and normal operations. When a nuclear reactor is shut down, it cannot be started without power for instrumentation, control system, coolant pumps, safety systems and many other support functions.

A typical plant arrangement may include both onsite and offsite power sources. These can be systems such as batteries, diesel engine-generators, gas turbine generators and external electric utility supplies.

Fukushima Daiichi had six external power supply sources, emergency diesel generators and backup battery systems. On the day of the incident, three of its reactors were operating. A 9.0 earthquake occurred and safety systems shut down the plant’s nuclear reactors, as designed. However, reactors contain residual heat immediately after a shutdown and depend on a cooling system to safely remove this heat.[11]

About 40 minutes after the earthquake, a tsunami with an initial wave over 14 meters (46ft) high and a second significant wave (8 minutes later) hit the site. These waves overwhelmed the plant’s protective sea wall, flooding the plant and submerging its residual heat removal pumps, diesel generators, batteries and much of the associated electrical power distribution equipment. All of these components were located in the basements of the reactor turbine buildings.

Ultimately reactors 1 through 3 all suffered varying degrees of core meltdown. Exposed fuel rods generated hydrogen gas and an explosion occurred in Unit 2. Radiation was released to both the atmosphere and the adjacent seawater, including iodine-131 with a half-life of 8 days and caesium-137 with a half-life of 30 years.

This serious accident resulted in the evacuation of 100,000 people. As of July 2020, over 41,000 people from Fukushima were still living as evacuees. People suffered significant trauma throughout this event, and the World Health Organization assessment notes post-traumatic stress disorder and other ongoing mental health problems for evacuees. [12]

The lessons learned from this incident are somewhat obvious:

- Don’t underestimate the power of natural events. Numerous studies showed that the frequency and severity of tsunamis had increased since the original design and construction of the plant’s protective sea wall. The plant owner/operator failed to take appropriate actions.

- It is a bad idea to locate critical backup systems in basements which are subject to flooding.

The Future

Generally, people get better at doing things over time. Even the undamaged TMI-1 reactor after its restart operated at very high levels of safety and reliability before being shut down in September 2019. In 1997 it completed the then longest period of uninterrupted operation for a light water reactor: 616 days and 23 hours.

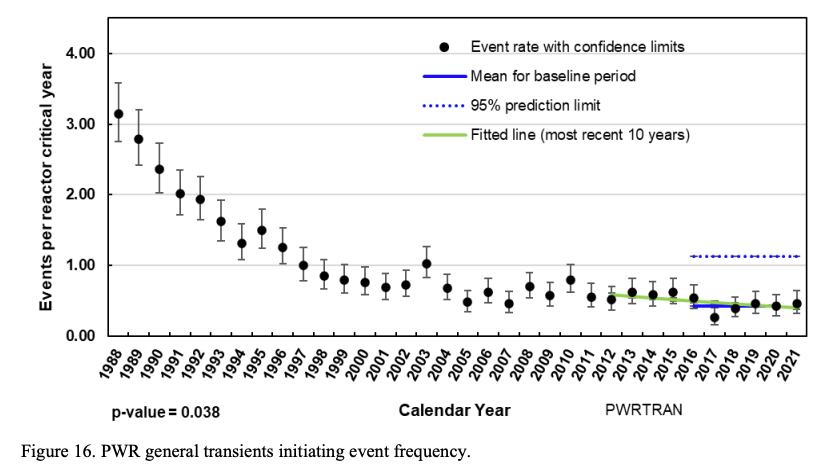

This diagram, from a report by Idaho National Laboratory [13], is another example of improved operations over time. In the parlance of the nuclear industry, general transients are a compilation of all reactor trip initiators that had no direct impact on systems to remove reactor heat. General transients include events such as manual reactor trip, turbine trip, spurious reactor trip, loss of non-safety related bus, and partial loss of feedwater.

The graph shows a decreasing rate of general transient events for PWR (pressurized water) reactors in the US. Operators have clearly gotten better at operating and maintaining these facilities over time.

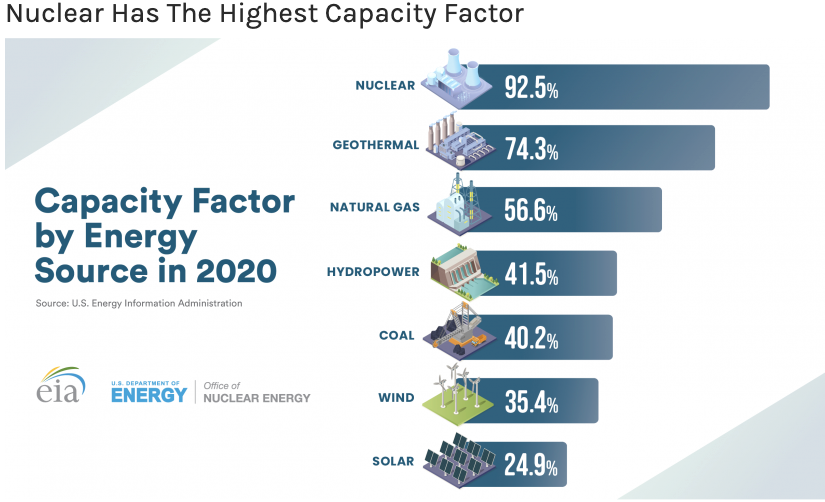

Nuclear generated power also has a capacity factor that is significantly better than any other power source. An indicator of reliability, capacity factor is a percentage calculated by dividing the actual unit electricity output by the maximum possible output for a given period of time, usually per year.

Summary

Nuclear energy has the potential to be a very important component in the battle to decarbonize electric grids throughout the world, significantly lowering GHG emissions. However, the issue of safety cannot be characterized in absolute terms and there’s no way 100% safe operation can be guaranteed.

Nuclear accidents can have both immediate and long-lasting effects on individuals and the environment. Each of us has a unique viewpoint on nuclear power and can have a voice, in some countries, on where and whether or not we choose to utilize this power source. There are some countries where citizens will have little say in the matter.

For the future and safety of all, the constructors of nuclear power plants need to exercise utmost care, and operators need to employ best practices from lessons learned. To maximize human performance, plant operators need to employ techniques such as artificial intelligence and machine learning in control and monitoring systems. Virtual digital twin models of nuclear facilities should be created and utilized for operator training and evaluation of “what if” scenarios. And, as history has shown, rigorous accountability and effective regulation are needed to prevent degradation of public safety due to industry complacency. I believe that with proper protocols and careful planning and operation, nuclear power can be safely used as one of the components in the battle against climate change.

[1] Nuclear Energy by Hannah Ritchie and Max Roser, Our World in Data https://ourworldindata.org/nuclear-energy

[2] Nuclear by the Numbers, Nuclear Energy Institute, August, 2020 https://www.nei.org/resources/fact-sheets/nuclear-by-the-numbers

[3] NY Times, Sunday, March 18, 1979, Section 2, “Nuclear Experts Debate ‘The China Syndrome’ “ and “… But Does It Satisfy the Nuclear Experts?”. https://timesmachine.nytimes.com/timesmachine/1979/03/18/issue.html

[4] World Nuclear Association, Three Mile Island Accident, April 2022, https://world-nuclear.org/information-library/safety-and-security/safety-of-plants/three-mile-island-accident.aspx

[5] Legal History of Three Mile Island, by Three Mile Island Alert http://www.tmia.com/old-website/history/tmilegalhistory.html

[6] World Nuclear Association, Chernobyl Accident 1986 (Updated April 2022) https://world-nuclear.org/information-library/safety-and-security/safety-of-plants/chernobyl-accident.aspx

[7] Harvard University, Science in the News, Radioactive Contamination Still Detected in Chernobyl Crops, January 11, 2021 https://sitn.hms.harvard.edu/flash/2021/radioactive-contamination-still-detected-in-chernobyl-crops/

[8] World Nuclear Association, RBMK Reactors — Appendix to Nuclear Power Reactors(Updated February 2022) https://www.world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-power-reactors/appendices/rbmk-reactors.aspx

[9] 2002 Davis-Besse Reactor Pressure Vessel Head Degradation Knowledge Management Digest NUREG/KM-0005 February 2014 Office of Nuclear Regulatory Research https://www.nrc.gov/docs/ML1403/ML14038A119.pdf

[10] US NRC, Backgrounder on Improvements Resulting From Davis-Besse Incident, June 2018 https://www.nrc.gov/reading-rm/doc-collections/fact-sheets/davis-besse-improv.html

[11] World Nuclear Association, Fukushima Daiichi Accident (Updated May 2022) https://world-nuclear.org/information-library/safety-and-security/safety-of-plants/fukushima-daiichi-accident.aspx

[12] World Health Organization, Radiation: Health consequences of the Fukushima nuclear accident 10 March 2016, Q&A https://www.who.int/news-room/questions-and-answers/item/health-consequences-of-fukushima-nuclear-accident

[13] Initiating Event Rates at US Nuclear Power Plants, 2021 Update, Nancy Johnson and Zhegang Ma, July 2022, Idaho National Laboratory https://nrcoe.inl.gov/publicdocs/InitEvent/initiating-event-frequencies-and-trends-2021.pdf

[14] 1979 NRC Annual Report, https://tmi2kml.inl.gov/Documents/4e-NRC-Annual/1979%20NRC%20Annual%20Report%20(NUREG-0690).pdf

[15] Associated Press, Judge Throws Out 2,000 Lawsuits by Three Mile Island Residents June 8, 1996 https://apnews.com/article/c24efcb5a4d1b61f83ad1142cd0b2464